- Need any help ?

- +91 94266 69363

- info@keplercast.com

Whether a valve housing or a modular conveyor or a machine component, the demand for precision castings made of steel alloys in various industrial sectors is enormous. Kepler cast provides the best manufacturing solution and produces complex castings with the highest precision using lost wax technology. Here through versatile industrial applications of our products in many different areas.

Based on the Lost wax technology we produce high quality products of intricate shapes and forms with an accurate precision. This process offers freedom of material, Shape, geometry and size, enabling us to produce based on customer specific requirements with a maximum efficiency. Focus of this process avoids the machining cost and material cost in comparison to other conventional production processes.

| Properties | Description |

|---|---|

| Shape tolerance | Freedom in style and design |

| Roughness | High surface quality & low roughness values (Ra 1.6 – 6.3 μm) |

| Dimensional tolerance | High dimensional accuracy and precise tolerances (Indian Standard 11166 – Class 2) |

| Materials | Virtually any steel alloy can be cast |

| Complexity | Complex shapes can be cast as a single component |

| Machining | Little to no machining is required |

| Undercuts | Products with undercuts can be cast |

| Series | Suitable for smaller and larger series |

A casting component that is produced at Kepler Cast, from idea to Implementation the focus stays on quality and thereby you opt for certainty and reliability. Each phase of development and production adheres to quality standards. Achievement of high surface roughness, high precision, significant degree of shape and geometry and application of versatile materials sets benchmark at Kepler Cast.

Traceability allow customer to track the product details from our digital records.

Scheduling algorithm at Kepler cast allow us to agree on customer order confirmation date and pre visibility of scheduling ensures the on-time commitment to customers thereby reduces the warehouse cost.

Supply chain process focus on Logistics costs, transit time, reliability and supply chain risk. Optimization and evaluation of logistics cost structure is a key factor that make products available to customer cost efficiently.

Key facets on optimization are Casting simulation, material reduction, Sprue cluster, gate formation and solidification analysis.

Type and identification of casting can be agreed with customer and on need customer wish marking methods can be applied.

High precision tool molding and Pre-Production samples ensures right product quality. Originality, Quickness and Cost effectiveness are benchmarks for Production at Kepler cast.

Our ERP System support diverse communication interfaces for data exchange electronically ensuring fast and accurate channel of communication.

Rapid prototyping generates a physical product based on the 3D model file for the design analysis and analyze the subassemblies.

With our rich experience in the area of precision casting, machining and prototyping will support you in an appropriate and right way.

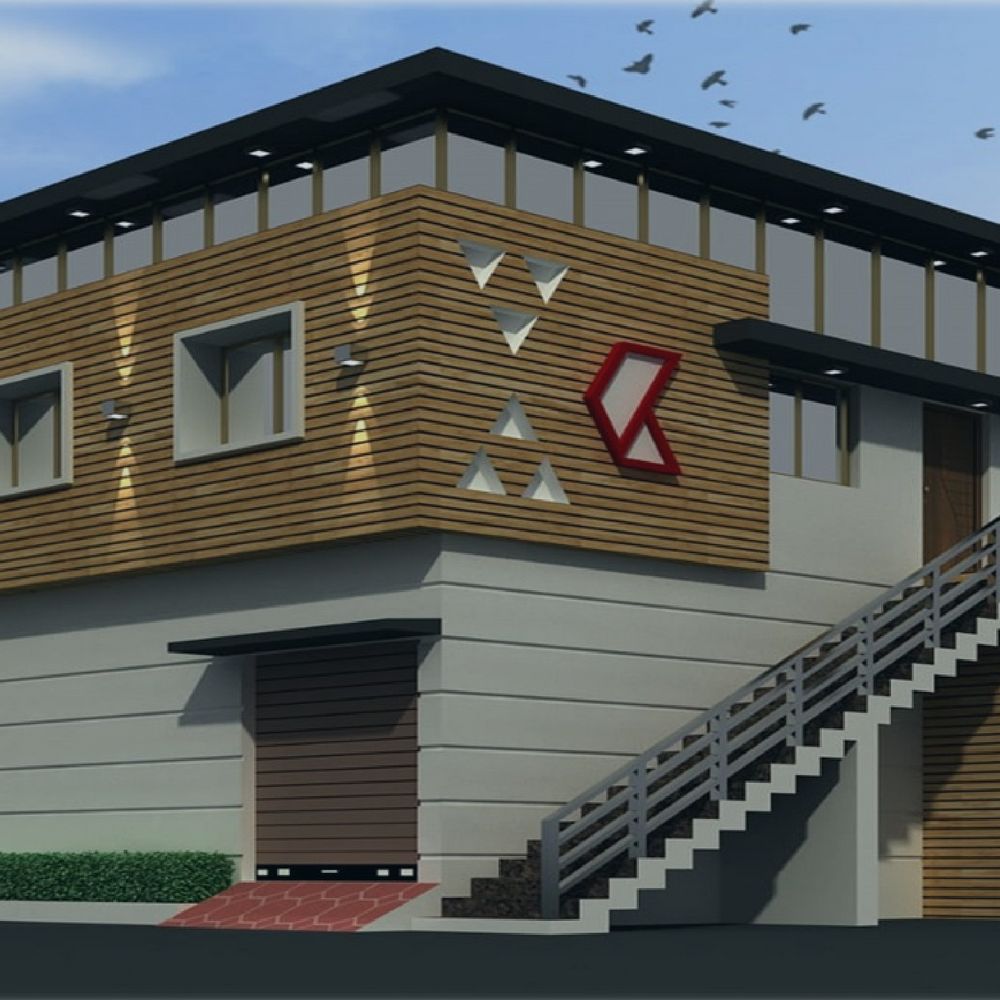

Kepler Cast is a development partner and producer of high-quality precision castings in stainless steel, produced according to the “Lost Wax” process. Kepler Cast has a modern state of the art facility at Rajkot in the state of Gujarat India. In addition, as a supplier, we are also the “preferred development partner” for various intricate steel components to various well-known customers.

We satisfy the high standards of quality in the sector concerning product quality, delivery reliability and process stability.

19 Years of rich industry experience in the metal field and transmitting the experience from one generation to the second motivated us in delivery of finished goods for our customers as single source solution.

Sharing the following information